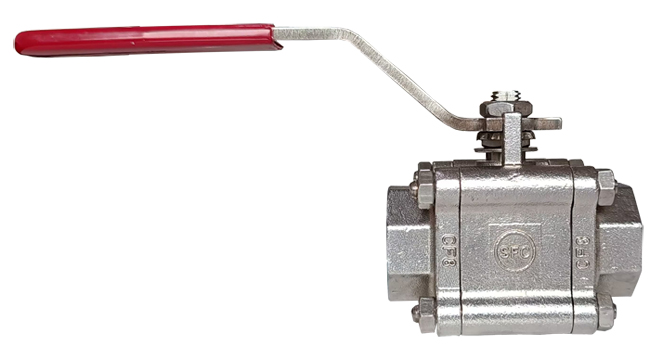

STARTFLO CONTROLS 3 PC (Three Piece) Floating Ball Valves are precision-engineered components designed to deliver reliable flow control in diverse industrial applications. These valves feature a modular three-piece construction, simplifying installation, maintenance, and replacement. Their floating ball mechanism ensures a secure seal by using line pressure to press the ball against the seat, reducing leakage risks. Constructed using premium MOCs such as CS (Carbon Steel), SS (Stainless Steel), Forged Carbon Steel, Cast Steel, or Cast Carbon Steel, Non-ferrous metal, these valves are capable of withstanding high pressure, extreme temperatures, and corrosive environments. They are widely utilized in industries requiring robust performance, including oil and gas, petrochemical, water treatment, and power generation.

When non-metal resilient seats are destroyed in a fire, the upstream medium pressure push the ball into the downstream metal seat lip to cut off the line fluid and prevent the internal leakage due to a secondary metal to metal seals

The stem is designed with integral T-type shoulder to provide blow-out proof effectively. It is internally inserted the backseat function to assure stem sealing safety at all pressure

Antistatic device between ball & stem & stem & body are assembled by a spring & a stainless steel ball, which ensure all metal valve parts are grounding.